|

|

|

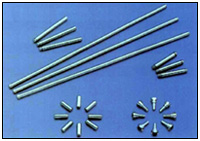

Pin wire / free-cutting wire |

| Introduction |

Non-magnetism, high strength and corrosion resistance are the basic requirements for the pin of audio, video & computer apparatus.

With the excellent experience in the past, we select the stainless steel wire rod which can correspond to above request. Combining the complete, detailed process and quality control, finished pin wire is lower magnetic property, high strength without surface defect.

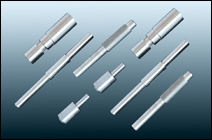

Due to the property emphasizing by CNC lathe or machine workshop customers, we especially select the superior quality of stainless steel wire rod in order to draw the free-cutting wire with good surface and cutting property. |

|

|

|

|

Pin Wire Product Grade |

| Product Grade |

Chemical Composition(%) |

| AISI |

SUS |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Other |

| 202 |

202 |

0.15 |

0.75 |

7.5-10.0 |

0.06 |

0.03 |

17.0-19.0 |

4.0-6.0 |

|

N:0.25 |

| 205 |

- |

0.12-0.25 |

0.75 |

14.5-15.5 |

0.06 |

0.03 |

16.5-18.0 |

1.0-1.75 |

|

N:0.32-0.40 |

| 202 |

202 |

0.07-0.10 |

1.0 |

9.0-10.0 |

0.03 |

0.03 |

17.5-18.5 |

5.0-6.0 |

|

N:0.25-0.35 |

| - |

304N2 |

0.06 |

1.0 |

2.5 |

0.035 |

0.01 |

18.0-20.0 |

8.0-10.0 |

0.5 |

Cu:0.5;

N:0.15-0.30 | |

| Free Cuting Wire Product Grade |

| Product Grade |

Chemical Composition(%) |

| AISI |

SUS |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Other |

| 303C |

303 |

0.15 |

1.0 |

2.0 |

0.2 |

0.15min |

17.0-19.0 |

8.0-10.0 |

0.6 |

- |

| 316F |

- |

0.08 |

1.0 |

2.0 |

0.045 |

0.1min |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

- |

| 416 |

416 |

0.15 |

1.0 |

1.25 |

0.06 |

0.15min |

12.0-14.0 |

- |

- |

- |

| 420F |

420F |

0.26-0.40 |

1.0 |

1.25 |

0.06 |

0.15min |

12.0-14.0 |

- |

|

- |

| 430F |

430F |

0.12 |

1.0 |

1.25 |

0.06 |

0.15min |

16.0-18.0 |

- |

|

- | | (We can provide other grades subject to your special requirement. )

|

|

| |

|